Hardware Basics | Tips and Tricks

CF Installation Troubleshooting Guide

If you have decided to upgrade to Emtek's CF 2.0 option for privacy and passage leversets, but are grappling with installation challenges, we have just the guide for you. Read on for our troubleshooting guide, where we break down the process step by step and help you recognize some of the common issues during the set up process for our concealed fastener mechanism.

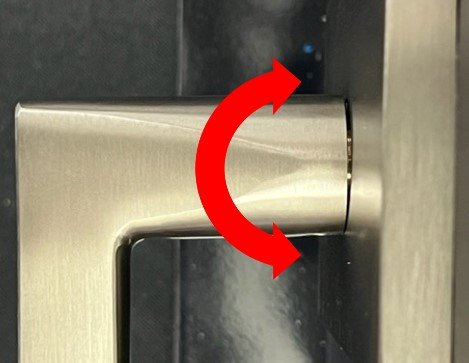

Issue: “Sagging levers” (Incorrect Clocking)

Cause: rotational location of Cassette.

Solution: Loosen cassettes and rotate opposite of sagging direction before retightening.

If door prep causes an extreme case, remove alignment device for greater adjustment.

Issue: Trouble tightening rosette ring

Cause 1: Rosette ring fastener was previously installed. Once installed, the thread locker is activated. The cured thread locker is difficult to remove and re-install.

Solution: Install new rosette ring fastener OR remove thread locker with wire brush.

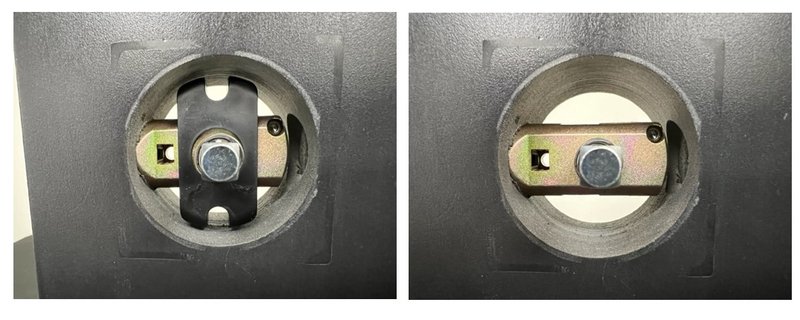

Issue: Trouble tightening rosette ring

Cause 2: Cassette hub is offset within cassette. If cassette is tightened on the door in this position, the close proximately can cause binding with the rosette ring fastener.

Solution: Loosen cassettes. Lightly push cassettes in the direction of the side with the small gap and retighten.

Issue: Trouble tightening rosette ring

Cause 3: Rosette ring fastener is not fully seated in the rosette.

Solution: Loosen rosette ring fastener and shift rosette until fastener is centered in rosette.

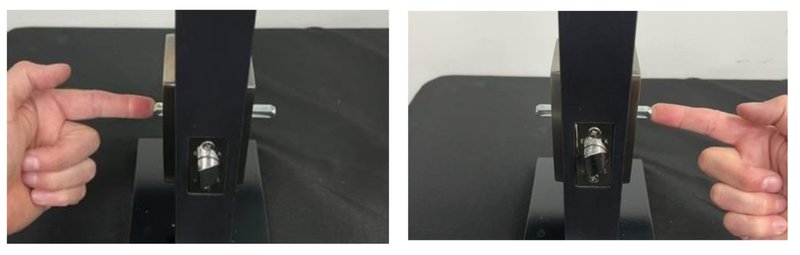

Issue: Gap between lever/knob and rosettes

Cause: Knobs/Levers not pushed together during installation.

Solution:

Step 1 - Disassemble rosettes and cassettes and rotate spindle ¼ turn to expose fresh surface for set screw and reassemble.

NOTE: This step is important so that the set screw does not slip back into the “dimple” in the previous location.

Step 2 - Reassemble cassettes and rosettes.

Step 3 – Find which side of the spindle will push inward, into the spring. Then push in the opposite end of the spindle, and install lever/knob together while tightening the set screw.

Step 4 – Install opposite knob/lever, pushing both levers together while tightening the second set screw.

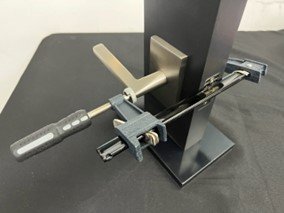

Note: a light duty clamp can be used to hold the parts in-place while tightening the set screws.

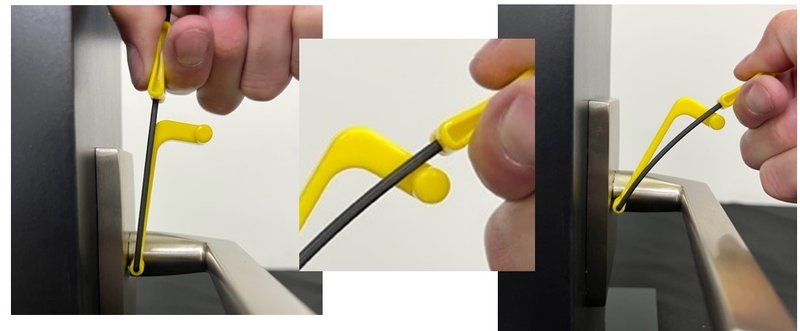

Step 5 – Tighten both set screws to approx. 15 in-lbs using supplied torque wrench. Needed torque is achieved when hex wrench touches round bump.

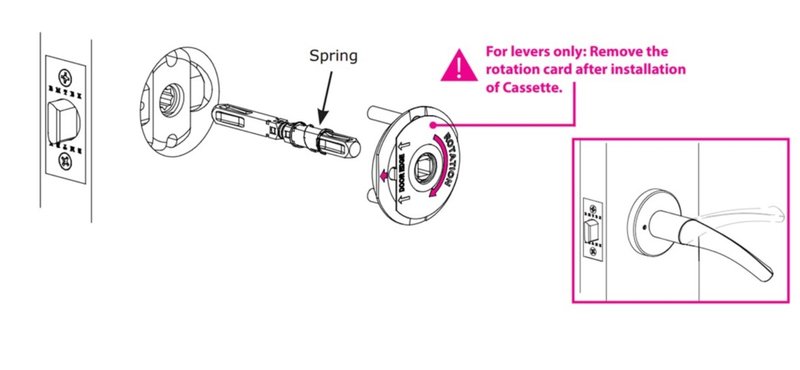

Issue: Lever/knob “loose”

Cause: The knob is not fully tightened to the spindle. Determine if set screw is loose by “wiggling” about the set screw axis and perpendicular to it. A difference indicates a loose set screw.

*NOTE: the Emtek Concealed Fastener lockset uses a different type of mechanism from the standard Emtek lockset. There is a mechanical difference in how the lever/knob “rests” in the assembly. If the lever is moved up and down, there is noticeable movement that should not be perceived as a loose installation.

Solution: Use the steps outlined in #3 above to rotate spindle to new surface and tighten to ~15 in-lbs using supplied torque wrench.